Barringer, Wallis & Manners Ltd & Metal Box

Barringer, Wallis & Manners Ltd & The Metal Box Company Ltd

Barringer Wallis and Manners Ltd was taken over by the Metal Box Company Ltd in 1939.

The following story is therefore split into two distinctive periods, the 1890’s to 1939 being the Barringer Wallis and Manners Ltd era, and 1939 to the 1990’s being the Metal Box Company Ltd era.

It is worth noting that the manufacture of trays, in particular brewery trays, formed only a very small part of both businesses.

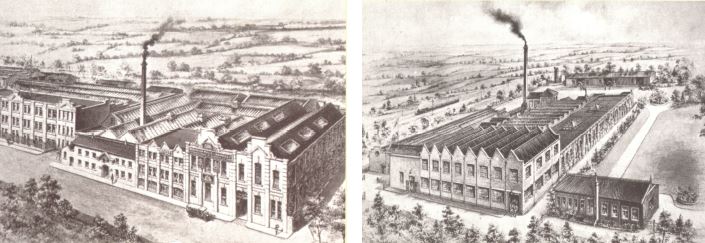

Two factories, one in Rock Valley, and the other on Oddicroft Lane, Sutton-in-Ashfield, specialised mainly in the manufacture of high quality decorative tin boxes.

The Origins of Barringer Wallis and Manners Ltd 1839 to 1895

When David Cooper died in 1861 his brother Robert Barringer purchased the business.

Robert Barringer was originally a tea salesman and he decided to enter into partnership with another tea salesman, Edwin Brown, forming Barringer and Brown.

Barringer and Brown packed the mustard in two ways; in wooden kegs for larger quantities and in tins for smaller quantities.

The smaller tins were hand made by their own workers.

Sometime in the early 1870’s Robert Barringer conceived the idea of packing the mustard in decorative tins, firstly as a larger size to the grocery trade (7lb & 4lb tins) and then crucially, in the mid 1880’s, directly to the customer in retail quantities (1lb down to 2oz).

Robert Barringer’s son, Walter Barringer, joined the business around that time as did Robert’s brother-in-law Isaac Wallis in 1879.

Isaac had a strong financial brain and was described as a ‘back room wizard’.

Robert Barringer retired in 1889 and was replaced by his entrepreneurial son in law, Charles Manners whereupon the tin-box business was separated from the mustard milling side. and was developed in its own right.

Two companies were formed: Barringer and Company, mustard manufacturers, and Barringer Wallis & Manners, tinplate decorators and printers.

Growth of the new business was accelerated in 1892 by the installation of a lithographic printing plant followed by the purchase of one of the first rotary printing presses in 1903.

Important customers such as Players Tobacco (Players Navy Cut tins) and famous individuals like Lewis Carroll (see picture of Alice in Wonderland tins), enabled the company to build its reputation quickly.

In 1895 the business was incorporated as a limited company becoming Barringer Wallis and Manners Ltd.

In addition to the Mansfield factory, the company also had an office in Fleet Street, London.

Barringer Wallis and Manners Ltd Expansion 1895 to 1914

The first directors of Barringer Wallis and Manners Ltd were:

Walter Barringer

Isaac Wallis

Charles Manners (Managing Director)

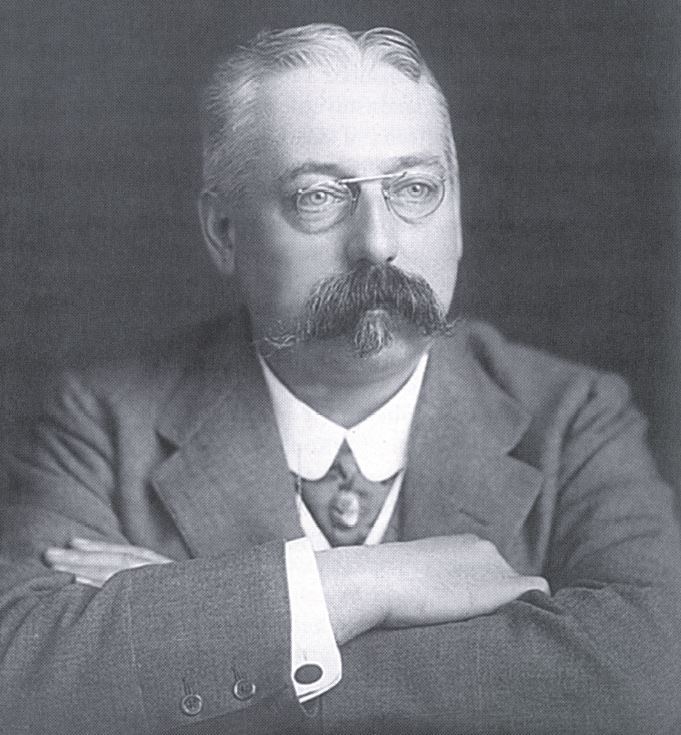

Another person to contribute to the early success of Barringer Wallis and Manners Ltd was William Holmes Reddan who joined the firm in 1896.

His knowledge of the printing trade, combined with excellent leadership and organisational skills were quickly recognised and within a short period of time he was elected to the Board of Directors.

When Charles Manners died suddenly in 1905 William Holmes Reddan took over as Managing Director, a position he occupied until his death in 1923.

As Barringer Wallis and Manners Ltd continued to grow and as demand outgrew supply, the company purchased a subsidiary factory for £2800 in Oddicroft Lane, Sutton-in-Ashfield in 1897.

A few years later the company sold the mustard milling business to Colmans of Norwich, and in 1918 the old Rock Valley mustard mill was purchased for tin printing and the manufacture of tin boxes.

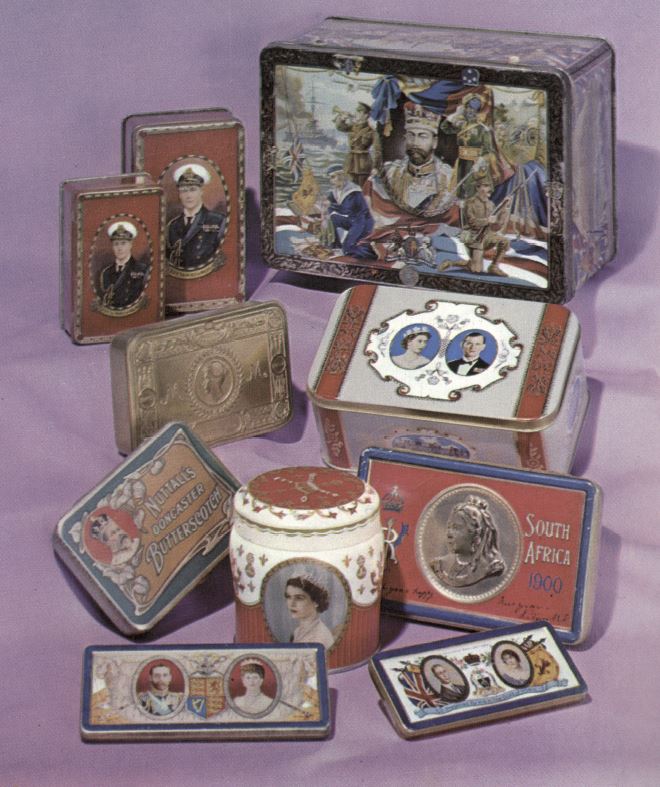

By 1914 the company was justly proud of the fact that they were the only tin-box manufacturers to be granted a succession of Royal Warrants.

These were bestowed by Queen Victoria, Edward VII, George V, Queen Mary and King Albert I of Belgium.

A series of commissioned royal boxes continued to increase the company’s reputation including:

Queen Victoria’s chocolate tin, which was sent to troops during the Boer War (1899-1902)

Princess Mary’s Gift Box , presented to members of the expeditionary force at Christmas 1914.

Souvenir tins were made for Edward VII and Queen Alexandra.

These are a few examples carrying a royal connection; there were many more, including other famous products like the Quality Street tin designed in-house by Charles Fletcher, one which still exists today.

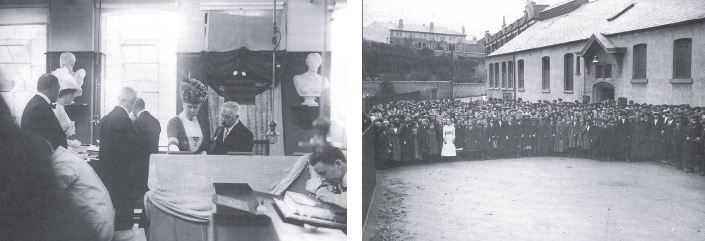

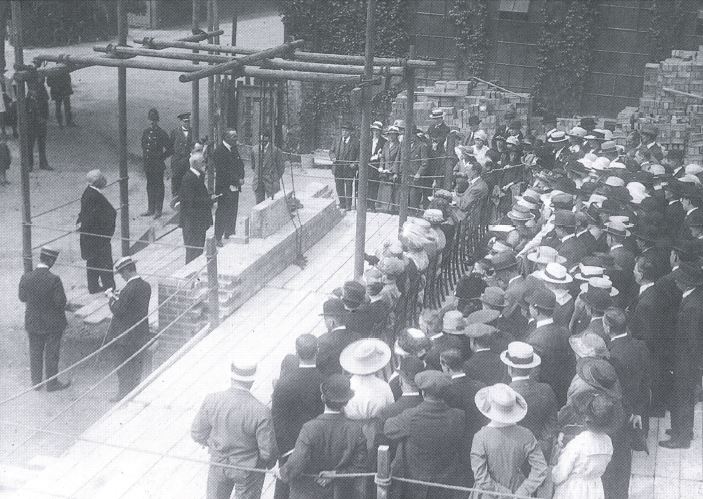

The royal connection gave Barringer Wallis and Manners Ltd their proudest moment when the Company was honoured with the visit of King George V, Queen Mary and other influential royal family members and dignitaries to the Rock Valley Works in June 1914.

A month later in July 1914 the nature of business was changed by the outbreak of World War I.

The Great War Years 1914 to 1919

During this period the resources at Rock Valley and Oddicroft Lane were placed at the Government’s disposal for the manufacture of supplies essential to the war effort.

Products which were produced by Barringer Wallis and Manners specifically for WWI included mess tins, ammunition boxes, shell cases, and war biscuit tins.

In addition the company manufactured canisters which were placed in the respirators issued to the troops for protection against poison gas, first used in May 1915.

Although the portfolio of non-military products changed during WWI the company did continue to manufacture a broad and diverse range of items.

A special catalogue, issued in 1916, pictured a number of premier decorated containers and examples included:

‘Moscow’ handkerchief box

‘Petrograd’ glove box

‘Telephone call’ moneybox

‘British Empire’ box

‘Warfare’ box depicting modern warfare

There were also tins for tobacco, cigarettes, snuff, pills, health salts, ointments, pen nibs, gramophone needles, typewriter ribbons, screws, nails and many other items.

Quality talcum powder tins attracted customers such as Yardleys, Boots and Cussons.

It is worth noting that brewery trays, or any trays for that matter, were not yet part of Barringer Wallis and Manners portfolio.

A great number of men from the two factories joined the British forces to fight on the front line leaving the women to work the machinery.

Sadly many men did not return.

Between the two Wold Wars 1919 - 1939

In 1919, a few months before the end of WWI, William Holmes Reddan laid the foundation stone for a new Tower Block and Clock Tower at the Rock Valley Works and this included a poignant speech about employees lost during the Great War.

This building, together with its clock and weather vane, gave Mansfield a new landmark with the clock the only part of the Rock Valley Works still standing today.

After WWI one branch of the firm’s activities, the manufacture of children’s toys, flourished.

When the import of toys dried up, Barringer Wallis and Manners Ltd decided to meet demand by manufacturing toys themselves.

The production of toys including motor cars, railway engines, aeroplanes and weapons, proved to be very successful, and was one reason the company was able to ride out the post war depression during the 1920’s.

However, decorative metal boxes, especially commemorative examples, biscuit tins, and tea containers provided the bulk of their manufacturing capacity during this period.

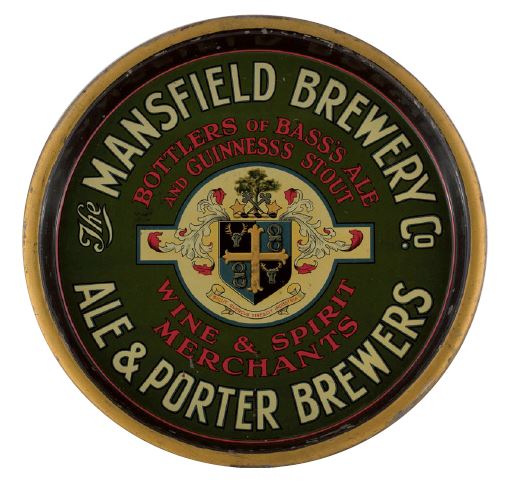

It is around the late 1920’s, most probably 1928 or 1929, that Barringer Wallis & Manners Ltd manufactured its first brewery tray.

According to Alan Atkins, who is the most knowledgeable person on the subject, ‘The earliest date for tray manufacture would probably have been the late 1920’s because the machinery required to produce trays were very big double action presses which were extremely expensive and required a solid foundation, that is a concrete floor, and therefore orders for trays had to be financially viable’.

Fittingly one of the first, if not the first, brewery tray, was produced locally for the Mansfield Brewery Co Ltd at the Rock Valley Works.

What a fantastic tray it was, depicting Mansfield Brewery Co Ale & Porter Brewers.

Mansfield brewery was also a bottler for both Bass’s Ale and Guinness Stout.

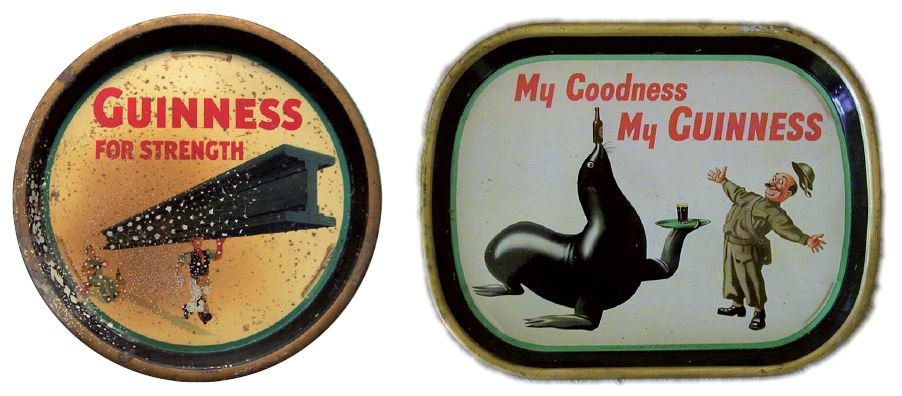

It was perhaps the fact that the Mansfield Brewery Co Ltd bottled Guinness Stout and their close location to the Rock Valley Works that Barringer Wallis and Manners Ltd were commissioned to produce the first heavy tin plate advertising trays by the famous designer John Gilroy.

Gilroy worked as an in-house artist at S.H.Bensons advertising agency and was responsible for designing the now famous ‘Guinness for Strength’ and ‘Guinness Zoo Animals’.

Barringer Wallis & Manners Ltd were the only company in the early to late 1930’s who manufactured waiter trays printed with the Gilroy designs.

It appears that the contract was eventually lost to Reginald Corfield Ltd in 1957.

I would dearly love to obtain two missing Gilroy trays for my collection, one depicting a man holding a girder with the slogan ‘Guinness for Strength’, and the other stating ‘My Goodness My Guinness’ with a sea lion balancing an old soldier’s bottle of Guinness on his nose.

Both trays were produced by Barringer Wallis & Manners Ltd in 1935 and 1940 respectively.

Unfortunately by the late 1930’s Barringer Wallis and Manners Ltd profits had been falling and therefore the Board of Directors approached Sir Robert Barlow of the Metal Box Company Ltd to explore a possible merger/acquisition.

The negotiation process, which had started in 1937, was finally settled in July 1939 when Barringer Wallis and Manners Ltd shareholders finally accepted an offer from the Metal Box Company Ltd to purchase the company.

Barringer Wallis and Manners was now part of the vast Metal Box empire which was one of the biggest companies in Britain.

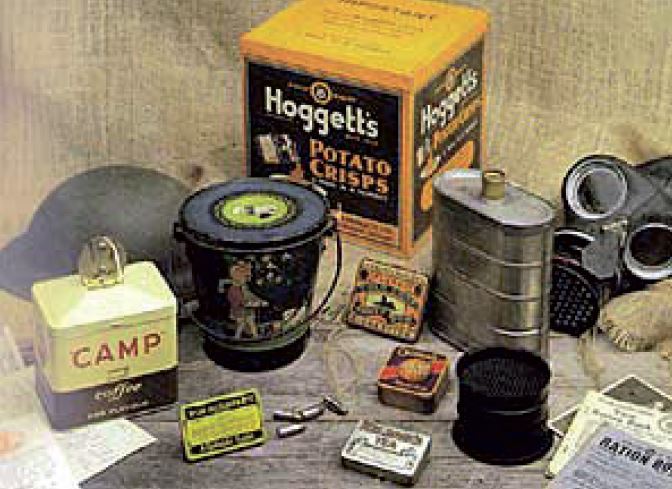

World War II 1939 – 1945

After becoming part of the Metal Box Company, business was once again affected by the outbreak of war.

Both factories became devoted to the manufacture of components to help efforts in WWII.

Products such as munitions components, respirators, mess tins and emergency ration containers took up most of their capacity.

Part of the Oddicroft Lane factory was seconded by the British Small Arms Company (B.S.A) whose personnel were employed on the manufacture of Sten guns, other gun parts and jig tooling.

In 1941 the Metal Box group managed to raise £5000 to build a spitfire aeroplane and as recognition of this effort one of these famous fighting planes was named ‘Metalbox’.

The Metal Box Years 1945 – 1980

After WWII the company continued to prosper.

By 1945 Barringer Wallis and Manners Ltd, now the Metal Box Company Ltd, had 2600 employees compared to 50 when it was incorporated in 1895.

The size of the company can be demonstrated by listing the manufacturing operations around that time.

Rock Valley included: a toy factory, press shops, tinplate slitting, irregular built up (IBU), Worcester ware, 9 ¼ line, seamless, fancy box, talcum, extrusion as well as all the support functions such as transport, despatch, engineering, work study, factory services, tool setting…etc

Oddicroft Lane included: a toy factory for Chad Valley, an Open Top factory, general line production, printing and once again all the relevant support functions.

After the war the manufacture of waiter trays was undertaken at the Rock Valley Works within the Press Shop. Female operators were required to sit in a well in order to operate tall presses and it was very heavy work. A Metal Box Company policy was to stamp out four trays per sheet of plate with a maximum of four print colours.

Government restrictions on the use of tin plate meant that all waiter trays between 1947 and 1953 were manufactured by Metal Box using aluminium.

Metal Box in Mansfield was given the number ‘MB 6’ and many waiter trays were simply stamped with this distinguishing code.

Towards the end of rationing, demand for decorated boxes grew again and business for both confectionery and biscuit tins boomed.

1953 Coronation tin sales were so great the Metal Box Company purchased an additional factory in Leicester, whilst in order to create additional capacity in Mansfield, a portion of waiter tray manufacturing, and associated equipment, was transferred to Liverpool.

Interestingly Metal Box in Liverpool, sited at Breeze Lane in Walton and Park Lane in Aintree, was known by the number ‘MB 8’ but local management chose not to stamp this on their trays.

Instead the full name was used - ‘The Metal Box Co Ltd (Liverpool Branch)’.

As a result of a business downturn in 1963, the manufacture of waiter trays ceased in Liverpool and once again all production was concentrated in Mansfield.

Between 1954 and 1961 a number of factors caused falling sales at the Metal Box Company.

Changes in lifestyle saw demand for fancy/decorated boxes decline drastically, an example being biscuit tin manufacturing which had taken two full production lines after WWII but was ultimately phased out completely by the mid 1960’s.

In addition there was a downturn in business with Chad Valley and some key USA customers, and this severely affected profitability with a wide range of products having to be discontinued.

A period of rationalisation took place with unprofitable products such as talcum powder tins being taken out and for the first time in their history job losses were enforced.

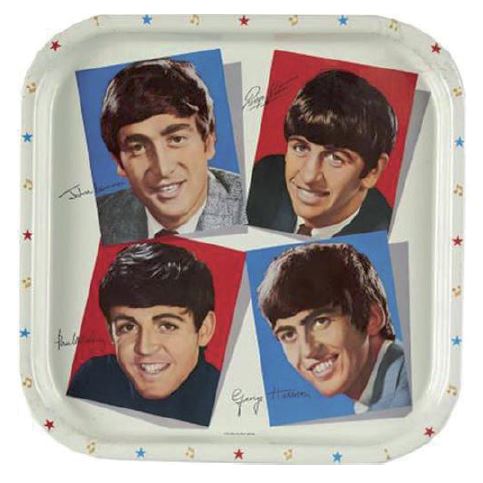

There were some successes however and one was trays, not brewery trays however, but the manufacture and sale of 180,000 Beatles trays in 1964.

Surprisingly only one design was produced, in the cold light of day an opportunity missed I think!

During the period 1967 to 1974 the company received further setbacks which included two fires at the Sutton factory, in August 1967 and September 1969.

The fires actually created an opportunity to modernise and install new plant and machinery and this was completed in record time despite major problems associated with fire damage.

Mass-produced aerosol containers were the boost that the Metal Box Company needed to once again stabilise and grow after that.

Brewery trays continued to be manufactured through the 1970’s and when in 1971 Hancock Corfield & Waller Ltd, one of Britain’s biggest manufacturers of drinks trays, decided to outsource their production to the Metal Box Company in Mansfield, continuation of this product line was assured.

Trays produced during this contract, which lasted to about 1976, were stamped with MB/HCW.

Tray manufacturing continued until at least the late 1970’s and in 1977 the company went back to their roots to produce commemorative items, in particular a tray portraying the Queen and Prince Philip for the Queen’s Silver Jubilee.

More than 300,000 of these trays were marketed both at home and in the Commonwealth.

Metal brewery trays had all but disappeared by the turn of the 1980’s and the Metal Box Company Ltd was the last major manufacturer of these wonderful items.

What better way to feel a sense of what it was like to work for the Metal Box Company Ltd through the voices of those who worked there between the 1950’s and the 1970’s.

Enjoy the video by clicking on the link below.

Mansfield MetalBox factory voices

However this was not the end for the company itself which at its peak employed over 3000 people with a significant proportion of these being women.

In the 1980’s and 1990’s market downturns resulted in further redundancies, however, albeit under different ownership and structure, the company has survived.

The Carnaud Metalbox name no longer exists as it was taken over by Crown Cork & Seal in 1996 which is now part of Crown Holdings Inc. with four divisions, Crown Aerosols, Speciality Packaging, Bevcan & Foodcan.

The Sutton site which is now owned by Crown Aerosols UK, currently employs 400 people and is the largest producer of aerosols in Europe.

The Rock Valley factory was sadly demolished in early 2010 however the Clock Tower does remain as nostalgic symbol of over 100 years of Mansfield manufacturing heritage.

For a spooky tour of the Clock Tower please click this video which was filmed in 2009

Metal Box Clock Tower Mansfield

The company, now named Crown Speciality Packaging plc, moved to Crown Farm Way, Forest Town in 2010 employing 100 people, and still manufactures ‘speciality biscuit, tea caddy and whisky tins’ today.

Conclusion

The Barringer Wallis & Manners Ltd and Metal Box Company Ltd story is a fantastic example of great British industry.

Although tray manufacturing was just a tiny part of a wide product portfolio it is still nevertheless an interesting tale in itself.

I would love to meet and interview anyone that worked in the press department in the Rock Valley factory.

In creating this story I am indebted to Alan Atkins who painstakingly answered many of my questions and also detailed answers given by Mr R.Jeffrey of the production details of beer trays at the Aintree factory of The Metal Box Co and help provided by Mrs Ann Stone who dealt with beer tray orders at the Mansfield Metal Box Co factory during her period in the Commercial Department.

Alan Atkins book, ‘Rock Valley and Oddicroft Lane Recollections’, was instrumental in enabling me to create this small piece.